Executive Summary

Choosing the right AI-powered defect detection platform can make or break your quality control initiative. This comprehensive guide compares the three leading solutions: Cognex ViDi (enterprise powerhouse), Landing AI (data-centric approach), and Roboflow (developer-friendly platform).

Quick Recommendation:

- Large Enterprise with Budget? → Cognex ViDi

- Mid-size Company, Limited Data? → Landing AI

- Developers/Startups/Prototyping? → Roboflow

Quick Comparison Table

| Feature | Cognex ViDi | Landing AI | Roboflow |

|---|---|---|---|

| Best For | Enterprise manufacturing | Data-centric approach | Developers & startups |

| Starting Price | $15,000+ | $5,000+ | Free tier, $250/mo |

| Setup Time | 2-4 weeks | 1-2 weeks | Hours to days |

| Technical Skill Required | Low | Low-Medium | Medium-High |

| Deployment Options | On-premise, edge | Cloud, on-premise | Cloud, API, edge |

| Industry Focus | Automotive, electronics | General manufacturing | Universal |

| Data Labeling | Basic | Advanced (data-centric) | Excellent tools |

| Pre-trained Models | Yes | Yes | Extensive library |

| Edge Deployment | Excellent | Good | Good |

| Support Level | Premium | Business | Community + Paid |

| Typical ROI Timeline | 6-12 months | 3-6 months | 1-3 months |

Cognex ViDi: The Enterprise Standard

Overview

Cognex is the 800-pound gorilla in machine vision. Their ViDi Suite combines traditional machine vision with deep learning for industrial defect detection.

Key Strengths

1. Industrial-Grade Reliability

- Proven in thousands of factories worldwide

- 99.9%+ uptime in production environments

- Extensive field testing and validation

2. Comprehensive Hardware Integration

- Works seamlessly with Cognex cameras and lighting

- Integration with PLCs, robotics, factory automation

- Complete turnkey solutions available

3. Domain Expertise

- Deep automotive and electronics experience

- Pre-configured solutions for common defect types

- Industry-specific training and best practices

4. Enterprise Support

- Dedicated field engineers

- 24/7 technical support

- On-site training and implementation assistance

Use Cases

Ideal For:

- Automotive part inspection (body panels, welds, castings)

- Electronics manufacturing (PCB, semiconductor)

- High-volume production lines (1000+ parts/day)

- Safety-critical applications

- Companies with existing Cognex infrastructure

Real-World Applications:

- BMW uses Cognex for body panel inspection

- Intel semiconductor wafer inspection

- Bosch automotive component QC

Pricing

License Cost: $15,000 - $100,000+ per line

- Base ViDi Suite license: ~$15K

- Per-camera licensing

- Additional modules for specific defect types

- Annual maintenance: 15-20% of license cost

Total Cost of Ownership (3 years):

- Small deployment (1-2 cameras): $50K - $100K

- Medium (5-10 cameras): $200K - $500K

- Large enterprise: $1M+

Hidden Costs:

- Cognex hardware (cameras, lighting, controllers)

- System integration services

- Training and certification

- Ongoing support contracts

Technical Details

Supported Defect Types:

- Surface defects (scratches, dents, discoloration)

- Assembly verification (missing/wrong parts)

- Measurement and gauging

- OCR and code reading

- Anomaly detection

Deployment Options:

- Cognex In-Sight cameras (embedded)

- Industrial PCs with frame grabbers

- Edge controllers for multi-camera systems

Integration:

- Factory automation protocols (EtherNet/IP, Profinet)

- OPC-UA for SCADA/MES integration

- REST APIs for custom applications

Pros and Cons

Pros:

- Battle-tested in production environments

- Excellent hardware-software integration

- Strong support and training

- Proven ROI in enterprise settings

- Handles challenging lighting and environmental conditions

Cons:

- Very expensive initial investment

- Vendor lock-in (proprietary format)

- Less flexible than code-based solutions

- Slow to adopt latest AI research

- Requires Cognex-certified integrators for complex deployments

Landing AI: The Data-Centric Platform

Overview

Founded by Andrew Ng (Google Brain, Coursera), Landing AI takes a data-centric approach to computer vision, focusing on data quality over model complexity.

Key Strengths

1. Data-Centric Methodology

- Systematic approach to improving data quality

- Tools for finding mislabeled or ambiguous data

- Active learning to minimize labeling effort

2. Small Data Specialization

- Works well with limited training data (100-500 images)

- Data augmentation and synthetic data generation

- Transfer learning from pre-trained models

3. Rapid Deployment

- Cloud-based platform (no infrastructure needed)

- Visual interface for non-technical users

- Quick iteration and model improvement

4. Academic Pedigree

- Based on cutting-edge research from Andrew Ng’s team

- Regular updates with latest AI techniques

- Strong focus on practical manufacturing applications

Use Cases

Ideal For:

- Mid-size manufacturers (50-500 employees)

- Companies with limited ML expertise

- New defect detection projects (no existing data)

- Rapid prototyping and POC validation

- Multiple small-volume production lines

Real-World Applications:

- Consumer electronics final inspection

- Packaging quality control

- Pharmaceutical tablet inspection

- Food and beverage container inspection

Pricing

Platform Access: $5,000 - $50,000+ per year

- Starter: $5K/year (1-2 use cases)

- Professional: $25K/year (unlimited projects)

- Enterprise: Custom pricing (includes support)

Deployment:

- Cloud inference: Pay per API call ($0.01-0.05/image)

- On-premise deployment: Additional licensing fee

- Edge deployment: Device licensing required

Total Cost of Ownership (3 years):

- Small deployment: $30K - $60K

- Medium deployment: $100K - $200K

- Large deployment: $300K+

Cost Advantages:

- No hardware requirements (cloud-based)

- Fast time to value (weeks vs months)

- Flexible scaling (pay as you grow)

Technical Details

Supported Defect Types:

- Surface defects and anomalies

- Assembly verification

- Classification tasks

- Object detection and localization

- Segmentation for complex defects

Deployment Options:

- Cloud API (RESTful)

- Docker containers (on-premise)

- Edge devices (Jetson, RPi with licensing)

- SDK for custom integration

Integration:

- REST API for any programming language

- Python SDK for advanced users

- Webhooks for real-time notifications

- Export models to ONNX, TensorFlow

Pros and Cons

Pros:

- Lower upfront costs than Cognex

- Works well with small datasets

- User-friendly visual interface

- Regular platform updates

- Flexible deployment options

- Strong focus on data quality

Cons:

- Less mature than Cognex (newer company)

- Fewer industry-specific pre-built solutions

- Cloud dependency (unless on-premise)

- Limited hardware integration compared to Cognex

- Less extensive support network

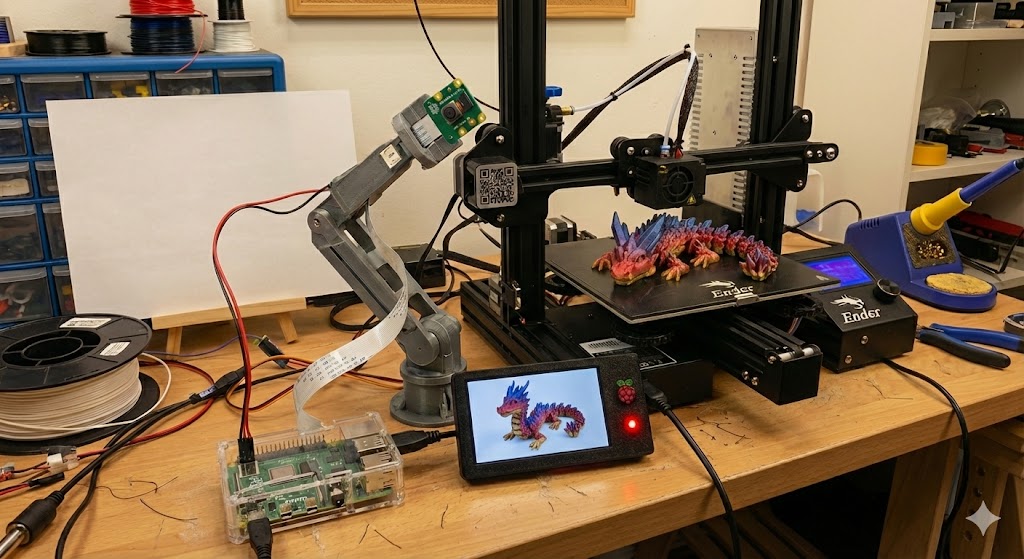

Roboflow: The Developer Platform

Overview

Roboflow is a complete computer vision platform designed for developers and data scientists. Think “GitHub for computer vision datasets.”

Key Strengths

1. Developer Experience

- Excellent documentation and tutorials

- Active community and extensive examples

- Python SDK and REST API

- Integration with all major ML frameworks

2. Data Management Excellence

- Best-in-class annotation tools

- Automatic data augmentation

- Dataset versioning and collaboration

- Public dataset library (100,000+ datasets)

3. Model Flexibility

- Train with YOLOv8, EfficientDet, or any model

- Export to 30+ formats

- Use your own models or Roboflow’s

- Full control over training pipeline

4. Rapid Prototyping

- Free tier for experimentation

- Deploy in minutes with hosted inference

- Quick iteration on models

- A/B testing different approaches

Use Cases

Ideal For:

- Startups and small companies

- Internal ML/CV teams

- Proof-of-concept projects

- Custom applications

- Developers who want full control

- Budget-conscious projects

Real-World Applications:

- Prototype defect detection systems

- Custom inspection solutions

- Research and development

- Training and education

- Side projects and MVPs

Pricing

Free Tier:

- Up to 1,000 images

- 1,000 hosted inference credits/month

- Community support

- Public projects only

Starter: $49/month

- 10,000 images

- 5,000 inference credits/month

- Private projects

- Email support

Professional: $249/month

- 100,000 images

- 50,000 inference credits/month

- Team collaboration

- Priority support

- Advanced features

Enterprise: Custom

- Unlimited images and inference

- On-premise deployment

- SLA guarantees

- Dedicated support

Additional Costs:

- Additional inference credits: $10 per 10K

- Auto-labeling: $0.01-0.05 per image

- Custom model training: Usage-based

Total Cost of Ownership (3 years):

- Hobbyist/POC: $0 (free tier)

- Small business: $1,800 - $9,000

- Growing company: $10K - $30K

- Enterprise: $50K+

Technical Details

Supported Models:

- YOLOv5, YOLOv8, YOLOv9

- EfficientDet

- Faster R-CNN

- Mask R-CNN

- Custom architectures

Deployment Options:

- Roboflow Hosted Inference API

- Export to TensorFlow, PyTorch, ONNX

- Docker containers

- Edge devices (Jetson, Coral, OAK)

- Mobile (iOS, Android)

Integration:

- Python SDK

- REST API

- JavaScript SDK

- iOS/Android SDKs

- Webhook notifications

Pros and Cons

Pros:

- Extremely cost-effective

- Fast iteration and experimentation

- Excellent developer tools

- Active community

- No vendor lock-in (export anywhere)

- Transparent pricing

- Great for learning and prototyping

Cons:

- Requires technical expertise

- Less hand-holding than enterprise vendors

- You own the implementation (DIY)

- Limited industry-specific solutions

- No hardware integration

- Community support on lower tiers

Head-to-Head Comparison

Ease of Use

Winner: Cognex ViDi

- Point-and-click interface

- Pre-configured workflows

- Extensive training materials

- Field engineers assist setup

Runner-up: Landing AI

- Intuitive visual interface

- Guided workflows

- Less ML expertise required

Requires Technical Skills: Roboflow

- Developer-focused

- Assumes Python/ML knowledge

- More configuration needed

Time to Production

Winner: Roboflow

- Deploy in hours for simple cases

- Quick iteration cycles

- Minimal infrastructure setup

Runner-up: Landing AI

- 1-2 weeks typical

- Cloud-based (no hardware wait)

- Guided setup process

Longest: Cognex

- 2-4 weeks minimum

- Hardware procurement

- System integration required

Accuracy and Performance

Winner: Cognex ViDi (for traditional manufacturing)

- Optimized for industrial conditions

- Handles challenging lighting

- Proven in production

Winner: Landing AI (for small datasets)

- Data-centric approach yields high accuracy

- Works with limited training data

- Good generalization

Winner: Roboflow (for custom solutions)

- Access to latest models (YOLOv8+)

- Full control over training

- Can match others with expertise

Total Cost Comparison (3-year)

Most Expensive: Cognex

- Small: $50K - $100K

- Medium: $200K - $500K

- Large: $1M+

Mid-Range: Landing AI

- Small: $30K - $60K

- Medium: $100K - $200K

- Large: $300K+

Most Affordable: Roboflow

- Small: $0 - $10K

- Medium: $10K - $30K

- Large: $50K+

Scalability

Best: Roboflow

- Pay as you grow

- No hardware constraints

- Easy to add new use cases

Good: Landing AI

- Cloud-based scaling

- Flexible licensing

- Can grow with your needs

Limited: Cognex

- Per-camera licensing

- Hardware capacity constraints

- Expensive to scale

Industry-Specific Recommendations

Automotive

Best Choice: Cognex ViDi

- Industry standard

- Safety certifications

- Proven in automotive plants

- Required by many OEMs

Alternative: Landing AI

- Good for tier 2/3 suppliers

- Faster deployment

- Lower cost

Electronics & PCB

Best Choice: Cognex ViDi

- Excellent for high-volume

- Precise measurements

- Clean room compatibility

Alternative: Roboflow

- Great for prototyping

- Custom board inspection

- R&D environments

Food & Beverage

Best Choice: Landing AI

- Handles natural variation well

- Quick setup for new products

- Good with packaging inspection

Alternative: Roboflow

- Budget-friendly option

- Flexible for changing products

Textiles & Fabrics

Best Choice: Landing AI

- Good with texture analysis

- Handles material variation

- Works with limited data

Alternative: Cognex

- High-speed web inspection

- Large format scanning

Pharmaceuticals

Best Choice: Cognex ViDi

- Regulatory compliance

- Audit trails and validation

- GMP documentation

Alternative: Landing AI

- Good for packaging inspection

- Tablet/capsule QC

Startups & Small Manufacturers

Best Choice: Roboflow

- Budget-friendly

- Learn as you go

- Scale when needed

Alternative: Landing AI

- More hand-holding

- Still affordable

- Better for non-technical teams

Decision Framework

Choose Cognex ViDi If:

- Budget > $100K available

- Large enterprise with existing Cognex infrastructure

- Safety-critical application

- High-volume production (1000+ units/day)

- Automotive or electronics industry

- Need 24/7 support and SLAs

- Prefer turnkey solution

- Risk-averse (proven technology)

Choose Landing AI If:

- Budget $30-100K

- Limited training data (< 500 images)

- Mid-size manufacturer

- Need quick time to value

- Non-technical team

- Multiple small production lines

- Data quality is a concern

- Want modern AI approaches

Choose Roboflow If:

- Budget < $30K

- Have technical team (Python/ML)

- Building custom solution

- Rapid prototyping needed

- Want full control

- Multiple use cases to experiment with

- Startup or small company

- Learning/education focus

Migration Paths

Starting with Roboflow, Moving to Landing AI

When to Migrate:

- Outgrown technical capabilities

- Need better support

- Want managed service

- Scaling beyond POC

Migration Process:

- Export Roboflow models

- Import datasets to Landing AI

- Retrain with their tools

- Timeline: 2-4 weeks

Starting with Landing AI, Moving to Cognex

When to Migrate:

- Need hardware integration

- Scaling to many lines

- Industry requirements

- Budget available for enterprise

Migration Process:

- Cannot directly migrate models

- Need to retrain in ViDi Suite

- Use Landing AI data for training

- Timeline: 1-2 months

Starting with Cognex, Moving to Others

When to Migrate:

- Rarely happens (lock-in)

- Cost reduction needed

- Want more flexibility

Migration Challenge:

- Proprietary format

- Need to re-annotate data

- Rebuild entire workflow

- Timeline: 2-3 months

Real Customer Stories

Success Story: Cognex

Company: Major automotive supplier (unnamed) Challenge: Inspect cast aluminum parts for micro-cracks Solution: Cognex ViDi Blue (anomaly detection) Results:

- 99.7% defect detection rate

- Reduced false positives by 85%

- $2M annual savings

- ROI in 8 months

Success Story: Landing AI

Company: Electronics manufacturer (50 employees) Challenge: Inspect PCB solder joints with limited examples Solution: Landing AI platform Results:

- Trained model with only 200 images

- 96% accuracy within 2 weeks

- $400K savings in first year

- Scaled to 5 production lines

Success Story: Roboflow

Company: Packaging startup (15 employees) Challenge: Detect label misalignment on custom packaging Solution: Roboflow + YOLOv8 Results:

- Built POC in 3 days

- Deployed for $49/month

- 94% accuracy

- Validated business model before hardware investment

Integration and Deployment

Edge Deployment Comparison

Cognex:

- Cognex In-Sight cameras (easiest)

- Industrial PCs (robust)

- Proprietary edge controllers

- Excellent performance

Landing AI:

- Docker containers

- Jetson devices (good support)

- Custom edge hardware

- SDK for integration

Roboflow:

- ONNX export to any device

- Jetson support (good)

- Raspberry Pi (limited)

- OAK devices (excellent)

- Full DIY flexibility

Cloud vs On-Premise

Cloud (Best: Landing AI, Roboflow)

- Fastest setup

- No infrastructure management

- Scalable inference

- Lower upfront cost

On-Premise (Best: Cognex)

- Data privacy

- No internet dependency

- Lower latency

- Regulatory compliance

Hybrid (All Support)

- Train in cloud

- Deploy on-premise

- Best of both worlds

Hidden Costs and Considerations

Cognex Hidden Costs

- Annual maintenance (15-20% of license)

- Hardware upgrades

- Certified integrator fees

- Training and certification

- Per-camera licensing for scaling

Budget 30-50% above initial quote

Landing AI Hidden Costs

- API usage charges (can scale with volume)

- On-premise deployment fees

- Professional services for complex cases

- Data labeling services

Budget 20-30% above base price

Roboflow Hidden Costs

- Engineering time (your team)

- Infrastructure for deployment

- Additional inference credits

- Auto-labeling charges

- Hardware for edge deployment

Budget for technical resources

Frequently Asked Questions

Can I train on one platform and deploy on another?

Partial Yes:

- Roboflow → Export to anywhere (ONNX, TF, PyTorch)

- Landing AI → Export ONNX models (with restrictions)

- Cognex → Proprietary format (locked in)

Do I need labeled data to start?

Depends:

- Cognex: Yes, but they can provide labeling services

- Landing AI: Yes, but need less (100-500 images)

- Roboflow: Yes, but has auto-labeling tools

Can these detect new/unknown defect types?

Anomaly Detection:

- Cognex ViDi Blue: Excellent for anomaly detection

- Landing AI: Good, improving

- Roboflow: Depends on model choice (some support it)

What about lighting sensitivity?

Most Robust: Cognex

- Handles varied lighting well

- Works with challenging industrial conditions

- Built-in preprocessing

Good: Landing AI, Roboflow

- Modern AI handles lighting variation

- May need controlled environment

- Data augmentation helps

Can I try before buying?

Cognex: POC/trial available (requires sales engagement) Landing AI: Demo/trial available (contact sales) Roboflow: Free tier (no credit card needed)

Expert Recommendations

For Risk-Averse Large Companies

Primary: Cognex ViDi

- Proven track record

- Enterprise support

- Industry acceptance

Backup: Landing AI

- Modern alternative

- Lower cost

- Growing reputation

For Innovative Mid-Size Companies

Primary: Landing AI

- Best balance of features/cost/support

- Modern AI approaches

- Good for multiple lines

Experiment: Roboflow

- POC new applications

- R&D projects

- Learn CV/ML

For Technical Teams & Startups

Primary: Roboflow

- Maximum flexibility

- Cost-effective

- No lock-in

Consider: Landing AI

- When scaling beyond POC

- If need more support

- For production deployment

Action Plan: Next Steps

1. Define Your Requirements

- Production volume (parts/day)

- Defect types to detect

- Accuracy requirements

- Budget range

- Timeline constraints

- Technical capabilities of team

2. Start with Proof of Concept

Option A: Low Budget (< $5K)

- Try Roboflow free tier

- Test with sample data

- Build basic prototype

Option B: Medium Budget ($5-20K)

- Landing AI trial

- Professional consulting

- Validate approach

Option C: Large Budget (> $50K)

- Cognex POC

- Full system design

- Integration planning

3. Measure Success Criteria

- Defect detection rate

- False positive rate

- Processing speed

- Integration effort

- User adoption

- ROI timeline

4. Get Expert Help

Consider hiring consultants who know all platforms:

- Unbiased recommendations

- Faster implementation

- Avoid costly mistakes

Conclusion

There’s no single “best” platform - the right choice depends on your specific needs:

Cognex ViDi dominates enterprise manufacturing with proven reliability and comprehensive support, but at a premium price.

Landing AI offers a modern, data-centric approach that works well for mid-size companies with limited training data and smaller budgets.

Roboflow provides maximum flexibility and affordability for technical teams who want full control and are comfortable with hands-on implementation.

Most Common Path:

- Start with Roboflow for POC and learning

- Graduate to Landing AI for production

- Consider Cognex when scaling enterprise-wide

Get Expert Guidance

Still not sure which platform is right for your application? We can help.

Free 30-Minute Consultation:

- Review your specific requirements

- Recommend best platform for your use case

- Provide implementation roadmap

- Connect you with vendors

Additional Resources

Platform Documentation:

Related Articles:

- Best Datasets for Defect Detection Training

- YOLOv8 PCB Defect Detection Tutorial

- Jetson Nano Defect Detection Setup

Community:

Last updated: December 2025. Pricing and features subject to change. Contact vendors for current information.

Discussion