Introduction to YOLO

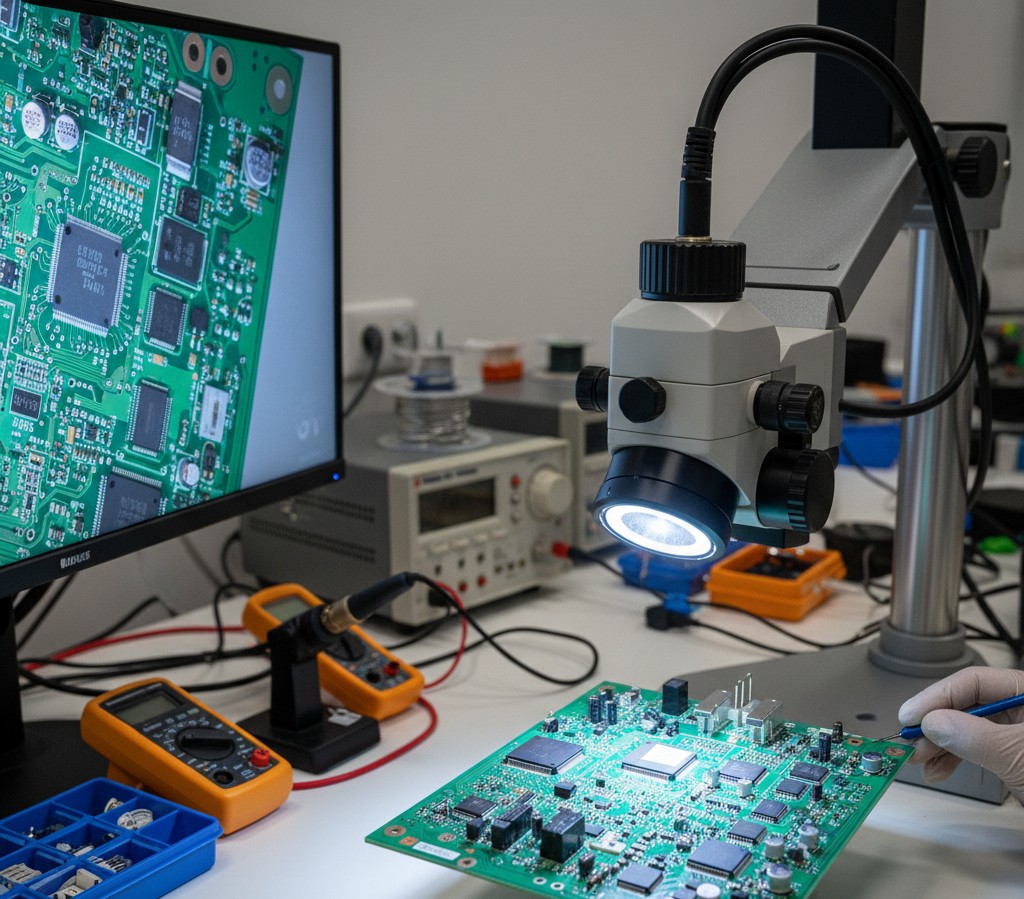

YOLO (You Only Look Once) has revolutionized real-time object detection, making it perfect for industrial defect detection applications where speed and accuracy are critical.

Why YOLO for Defect Detection?

- Real-time Processing: 30+ FPS on modern GPUs

- Single-stage Detection: Fast and efficient architecture

- High Accuracy: State-of-the-art results on various datasets

- Easy to Train: Transfer learning from pre-trained models

Setting Up Your Environment

1

2

3

4

5

6

# Install required packages

pip install ultralytics opencv-python numpy

# Import libraries

from ultralytics import YOLO

import cv2

Training Your First Model

1. Prepare Your Dataset

Organize your data in YOLO format:

1

2

3

4

5

6

7

dataset/

├── images/

│ ├── train/

│ └── val/

└── labels/

├── train/

└── val/

2. Create a Configuration File

1

2

3

4

5

6

# data.yaml

train: ./dataset/images/train

val: ./dataset/images/val

nc: 5 # number of classes

names: ['scratch', 'crack', 'dent', 'corrosion', 'missing']

3. Train the Model

1

2

3

4

5

6

7

8

9

10

model = YOLO('yolov8n.pt') # Load pretrained model

# Train the model

results = model.train(

data='data.yaml',

epochs=100,

imgsz=640,

batch=16,

device=0 # GPU device

)

Real-time Detection

1

2

3

4

5

6

7

8

9

10

11

# Load trained model

model = YOLO('best.pt')

# Run detection on image

results = model('defect_image.jpg')

# Display results

for r in results:

im_array = r.plot()

cv2.imshow('Defect Detection', im_array)

cv2.waitKey(0)

Performance Optimization

Tips for Production Deployment

- Use TensorRT for faster inference

- Optimize image size based on your defect sizes

- Implement batching for multiple images

- Use confidence thresholds to reduce false positives

Results

On a typical PCB defect dataset:

- mAP@50: 94.5%

- Inference Time: 28ms per image

- False Positive Rate: < 2%

Conclusion

YOLO provides an excellent balance of speed and accuracy for defect detection applications. With transfer learning and proper dataset preparation, you can achieve production-ready results quickly.

Next Steps

- Fine-tune hyperparameters

- Experiment with different YOLO variants (YOLOv8s, YOLOv8m)

- Deploy to edge devices

- Implement active learning pipeline

Recommended Resources

Want to learn more? Check out these resources:

- Hands-On Machine Learning Book - Comprehensive ML guide including computer vision

- NVIDIA RTX GPU - Recommended for training YOLO models

- YOLOv8 Official Documentation - Complete guide and examples

Note: Some links are affiliate links that help support this blog at no cost to you.

Have questions? Contact us or leave a comment below!

Discussion